To preserve the freshness of their vibrant farm-to-table ingredients, Gusto needed a way to monitor the conditions of food in their cold storage and salad wall around the clock. Gusto needed to be confident that the temperatures in food storage areas were accurate and auditable. Furthermore, as freshness is central to their mission, all members of the team are obligated to be aware of food quality and conditions. This requires automated monitoring and alerting as well as the ability to direct in-store team members from anywhere.

Shortly after installing wireless sensors and implementing the OpSense monitoring platform, a freezer at one of Gusto’s restaurants began to fail. The alert gained the immediate attention of a cross-section of people at the restaurant and at corporate operations resulting in saving thousands of dollars of product. Besides saving existing inventory, the alert avoided costs associated with the effort, labor and time needed for product replacement. In this instance, there were Gusto-proprietary items that are not available off the shelf. As a result, the items must be sourced and moved from other Gusto locations to the affected store. This activity is costly as it displaces the labor from multiple locations from their normal daily tasks so as to prepare the items for sale at the affected location. Ultimately, this limits inventory in multiple locations which can result in a general loss of sales.

There is also the avoidance of the costs associated with the ripple effect or multiplier that occurs when a restaurant loses product. Besides the direct cost of product lost, there is a direct impact on sales for that day until the product is replaced. This is further exacerbated as the standard response to inconveniencing in-store customers includes the practice of providing “free meal” coupons for a later date - when inventories are available. This practice is meant to avoid negative reviews on social media so as to reduce impact on the branch as well as to retain customers. Thus, OpSense monitoring saved product and eliminated potential direct and indirect revenue loss.

“OpSense provides real peace of mind that the ingredients we’re serving are in an optimal environment.”

Stephen Smittle

Chief Operating Officer

Round-the-clock monitoring helps your restaurant meet food safety guidelines such as HACCP and FSMA consistently, rather than costly and error-prone manual observation. OpSense is delivers quick ROI while providing actionable insights that increase food safety and staff efficiency.

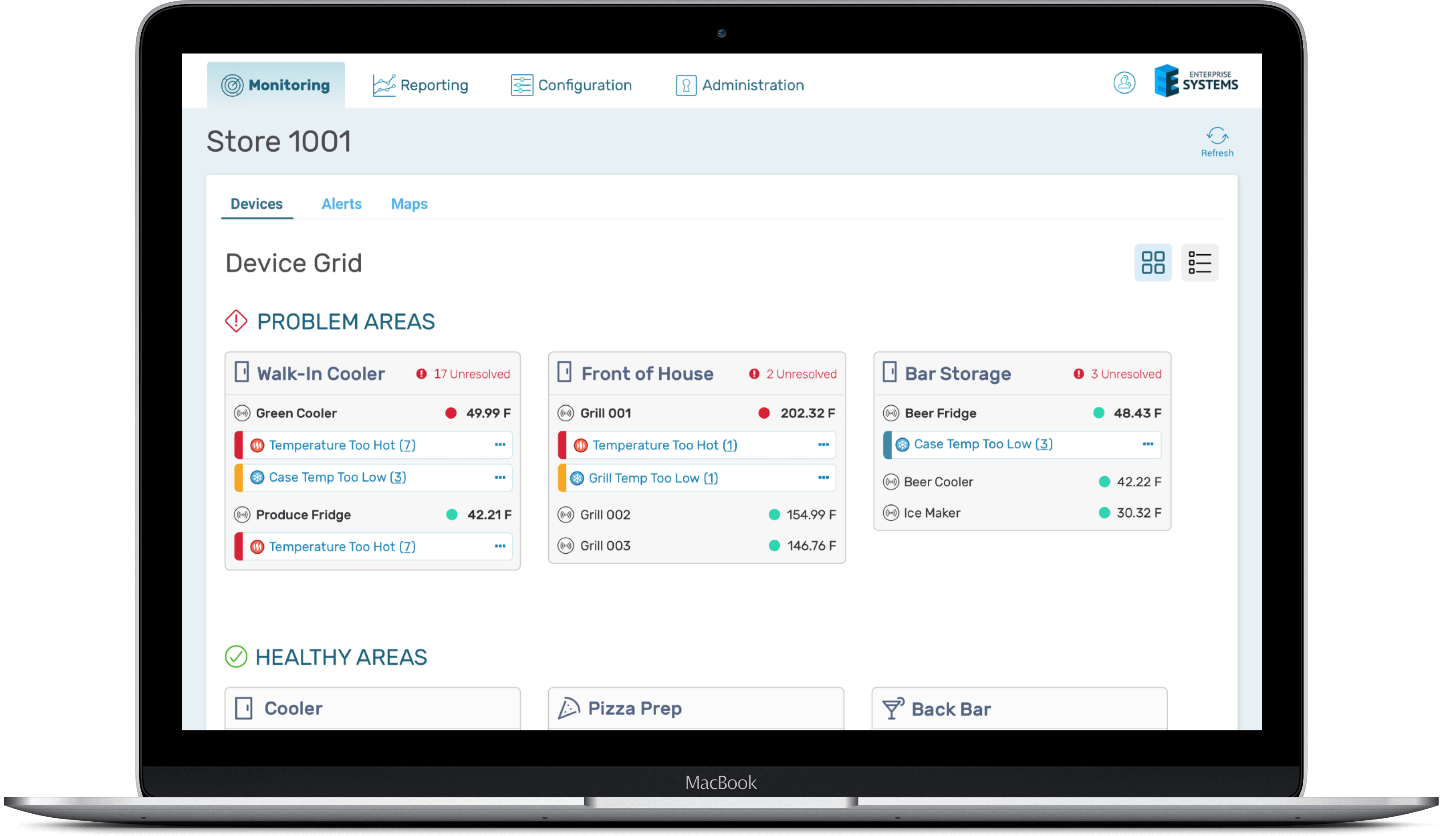

Designed to meet the needs of today’s restaurants, OpSense gives management teams visibility and quality control. The wireless sensor network can monitor temperature, humidity, open doors, HVAC conditions, lighting, wait times, sound, weight, voltage, and other critical operations such as task management, checklists, equipment, and energy costs for a true 360-degree view of your business. OpSense supports industry-leading protocols, including Bluetooth, LoRa, and Zigbee. Existing or client-preferred sensors may be incorporated so long as they align to standard industry protocols. Our scalable cloud-based architecture is designed to integrate with existing back-office platforms.